Powder filling is a crucial step in the manufacturing process of various products, ranging from pharmaceuticals and food items to cosmetic and industrial applications. The process involves several steps, each designed to ensure precision, efficiency, and product quality. In this article, we will explore what is the process of powder filling, from measuring and filling to capping and labeling.

Measuring the powder:

The first step in powder filling is accurate measurement. This involves determining the right quantity of powder to be dispensed into each container. The precision of this step is vital to ensure that each product meets the specified requirements and maintains consistency. Various measuring devices such as auger fillers, volumetric fillers, and gravimetric fillers are commonly employed depending on the characteristics of the powder.

Filling process:

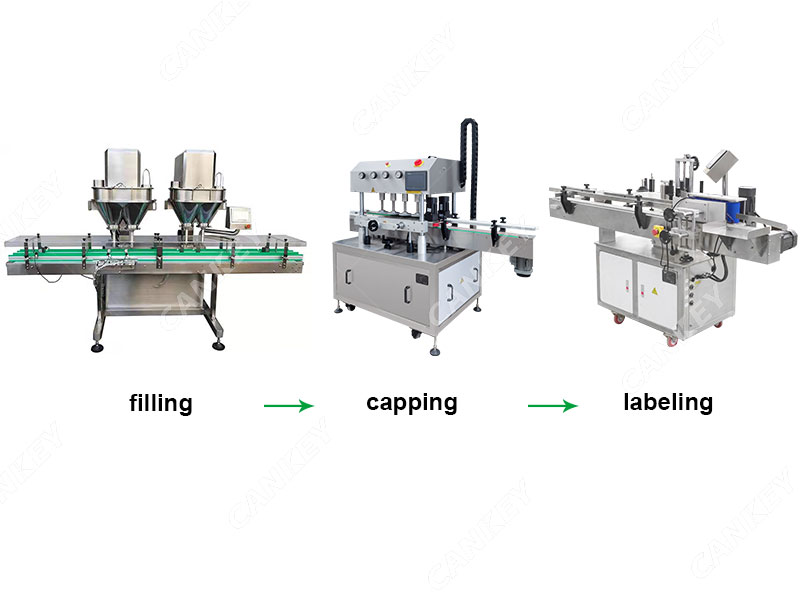

Once the powder is accurately measured, the filling process begins. There are different types of filling machines, each with its own mechanism. Auger fillers use a rotating screw to dispense powder, volumetric fillers rely on volume measurements, and gravimetric fillers use weight-based measurements. The choice of filler depends on the type of powder and the desired production speed.

Capping:

After the containers are filled with the powder, the next step is capping. This involves sealing the containers to protect the contents from external factors such as moisture, air, and contaminants. Common capping methods include screw capping, snap capping, and press-on capping. The choice of capping method depends on the type of container and the specific requirements of the product.

Quality control:

Quality control is an integral part of the powder filling process. Various inspections and tests are conducted to ensure that the filled containers meet the required standards. This includes checks for proper filling levels, cap tightness, and overall product integrity. Any deviations from the quality standards are identified and addressed to maintain the consistency and quality of the filled products.

Labeling:

Once the containers are filled and capped, the next step is labeling. Proper labeling is essential for product identification, regulatory compliance, and consumer information. Labels typically include product names, batch numbers, expiration dates, and other relevant information. Automated labeling machines are often used to ensure accuracy and efficiency in this step.

The powder filling process is a multi-step operation that demands precision, efficiency, and strict quality control. From measuring the powder to labeling the final product, each step plays a crucial role in ensuring that the filled products meet the required standards. As technology advances, new innovations in powder filling machinery and automation continue to enhance the accuracy and efficiency of the powder filling process, contributing to the overall quality of the final products.