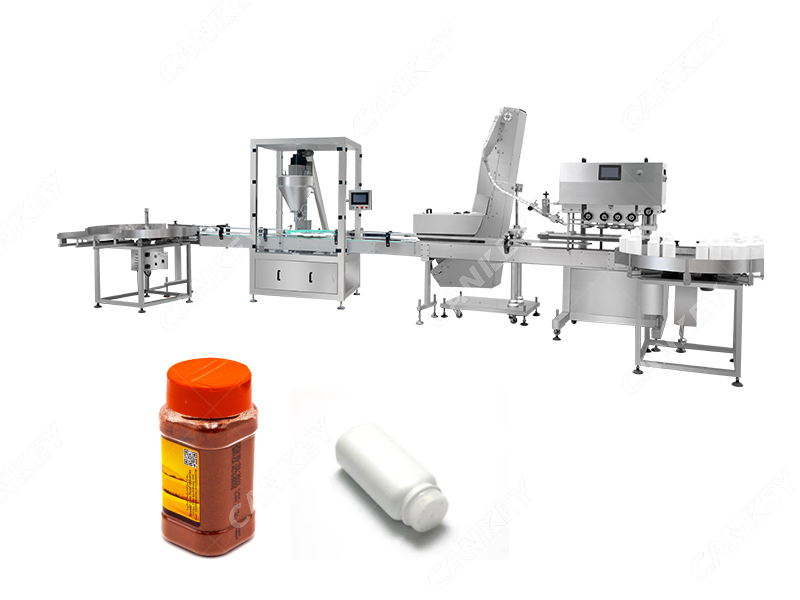

Powder filling machines are essential tools in various industries, from pharmaceuticals to food production. These machines play a crucial role in streamlining the packaging process and ensuring the efficient and accurate filling of powdered products. Do you know how fast is a powder filling machine? In this article, we will delve into the speed of powder filling machines, which typically ranges from 10 to 200 bottles per minute. We’ll explore the factors that influence this speed and the implications it has for different industries.

Understanding the range of speed

Powder filling machines come in a wide range of models, each with its own specific capabilities. The speed of these machines can vary significantly, but a common speed range is between 10 and 200 bottles per minute. This range encompasses various machine models, from semi-automatic to fully automated ones. As a general rule, the more automated a machine is, the faster it can operate.

Factors influencing speed

- Machine model: The specific model of the powder filling machine is a significant factor. Semi-automatic machines, which require more manual intervention, tend to have lower speeds, while fully automated machines can achieve much higher speeds.

- Powder characteristics: The nature of the powdered product being filled can affect the machine’s speed. Factors like powder density, flowability, and cohesiveness can impact the efficiency of the filling process.

- Filling mechanism: Different machines utilize various filling mechanisms, such as auger filling, piston filling, or gravity filling. The mechanism chosen can influence the speed and accuracy of the filling process.

- Container type and size: The size and type of containers being filled, whether they are bottles, jars, or bags, can impact the machine’s speed. Smaller containers may allow for faster filling than larger ones.

- Operator skill: For semi-automatic machines, the skill and experience of the machine operator can play a role in determining the speed and accuracy of the filling process.

Industry applications

- Pharmaceutical industry: In the pharmaceutical sector, precision and hygiene are critical. Fully automated high-speed filling machines are often used to ensure accurate dosage and maintain the integrity of the product.

- Food and beverage industry: Powder filling machines in the food and beverage industry must meet strict hygiene and safety standards. The choice of machine and its speed depends on the specific product being packaged.

- Chemical industry: The chemical industry often requires the filling of powders with varying properties. Speed and accuracy are essential to prevent spillage and ensure product quality.

The speed of a powder filling machine is a crucial factor that varies between 10 to 200 bottles per minute, depending on the machine model and specific requirements. Businesses must consider their industry, the nature of the powder, and the packaging needs when selecting a powder filling machine. While a faster machine can increase production efficiency, it is essential to balance speed with precision and product integrity, ensuring that the chosen machine aligns with the unique demands of the industry and the characteristics of the powdered product being filled.