Liquid filling machines have revolutionized the manufacturing industry by streamlining the process of filling containers with various liquids. These machines offer speed, accuracy, and efficiency, enabling businesses to meet high production demands effectively. To achieve their impressive performance, automatic liquid filling machines consist of several essential components that work together seamlessly. Do you know what are the components of a liquid filling machine?

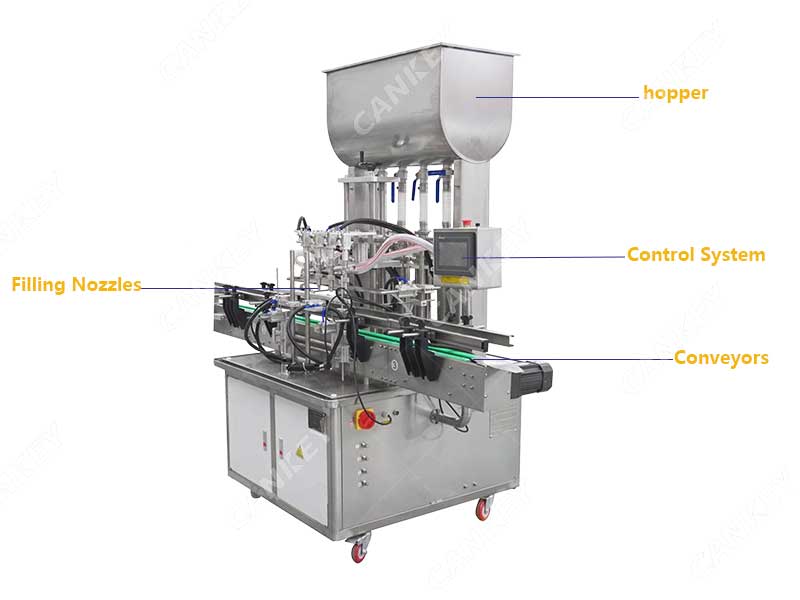

Hopper:

The hopper is the primary component of a liquid filling machine and serves as a reservoir for the liquid to be filled. It can hold a significant volume of liquid, allowing for continuous and uninterrupted filling operations. The hopper is usually equipped with sensors to monitor the liquid level and trigger refilling when necessary.

Conveyor:

Conveyors play a crucial role in transporting empty containers to the filling station and moving filled containers away from the machine. These systems can be belt conveyors, roller conveyors, or other types depending on the specific requirements of the production line. Efficient conveyor systems ensure a smooth flow of containers, minimizing downtime and maximizing productivity.

Filling Nozzles:

Filling nozzles are responsible for dispensing the liquid into the containers accurately. They are designed to control the flow rate and prevent spillage or overfilling. The number of filling nozzles may vary depending on the machine’s configuration, allowing for single or multiple simultaneous filling operations.

Pumps:

Pumps are the heart of the filling machine, as they create the necessary pressure to move the liquid from the hopper to the filling nozzles. Various pump types can be used, including peristaltic pumps, piston pumps, or rotary pumps. Each pump type offers different advantages in terms of accuracy, viscosity handling, and maintenance requirements.

Control System:

The control system of a filling machine encompasses a combination of hardware and software components. It manages and coordinates the different machine functions, including liquid level sensing, pump control, nozzle activation, and conveyor movement. Advanced control systems incorporate user-friendly interfaces, allowing operators to set parameters, monitor the filling process, and troubleshoot issues easily.

Sensors and Detectors:

Liquid filling machines are equipped with sensors and detectors to ensure accurate filling and prevent any potential issues. These sensors can include level sensors to monitor the liquid level in the hopper, container presence sensors to detect the arrival of containers, and leak detectors to identify any leaks or spills during the filling process.

Capping or Sealing Mechanism:

In some cases, the machines may also include a capping or sealing mechanism as an additional component. This mechanism ensures that containers are properly sealed after filling, maintaining product integrity and preventing leakage. The capping mechanism can be designed to handle various types of caps, such as screw caps, snap-on caps, or induction seals.