In the fast-paced world of food production, efficiency and accuracy are paramount. Manufacturers are continually seeking innovative solutions to optimize their processes and deliver high-quality products to meet consumer demand. One area that has witnessed significant advancements is the nutritional powder filling line. This cutting-edge technology streamlines production, enhances precision, and ensures the consistent packaging of powdered nutritional supplements.

Nutritional Powder Filling and Sealing Machine Includes:

Bottle unscrambler – Automatic feeder – Nutritional powder filling machine – Capping machine (or sealing machine) – Labeling machine – Chain plate conveyor – Packing platform; The filling line configuration can be selected according to the packaging requirements of the product.

Nutritional Powder Filling Machine Application:

All powdered materials, such as protein powder, talcum powder, spice powder, milk powder, cocoa powder, powdered sugar, medicinal powder, chemical powder, etc.

Powder Filling and Sealing Machine Features:

Enhanced efficiency: Automatic powder filling equipment revolutionize the production process by eliminating manual labor and significantly reducing the time required to fill and package powdered supplements. These automated systems are designed to handle large quantities of product efficiently and seamlessly. By automating the filling process, manufacturers can achieve higher production rates, minimize downtime, and increase overall operational efficiency.

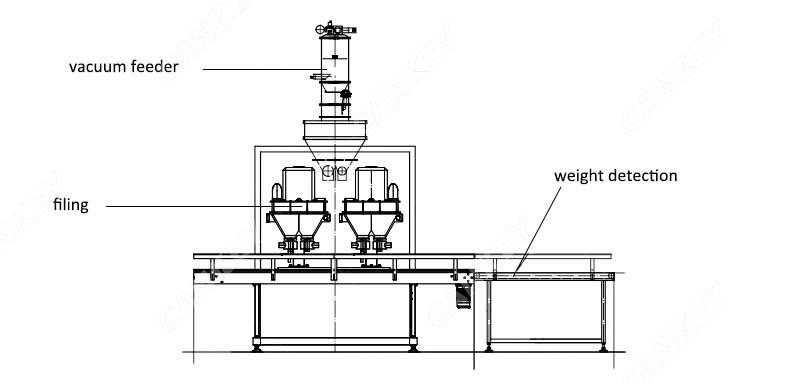

Precision and accuracy: One of the key advantages of nutritional powder filling machine line is their ability to deliver precise and accurate measurements consistently. These advanced machines utilize sophisticated technology, such as load cells and sensors, to measure and control the exact quantity of powder dispensed into each container. This level of precision ensures that every product adheres to the specified weight or volume, meeting stringent quality standards. The elimination of human error results in a significant reduction in product waste and variation, ultimately enhancing customer satisfaction.

Versatility and flexibility: Nutritional powder filling lines are designed to accommodate a wide range of container sizes, shapes, and materials. Furthermore, the equipment can handle various types of powdered nutritional supplements, including protein powders, meal replacements, vitamins, and dietary supplements. This versatility allows manufacturers to quickly switch between different products, maximizing production capacity and responding to market demands swiftly.

Reviews

There are no reviews yet.