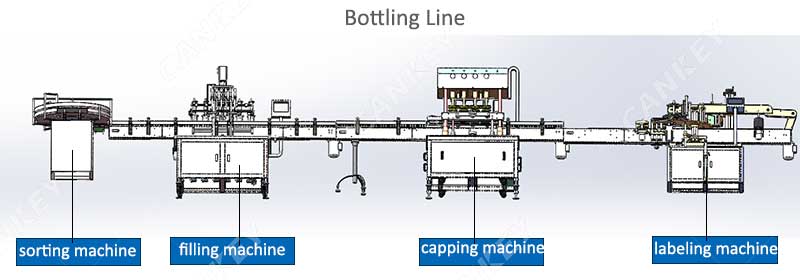

The beverage industry has witnessed significant advancements in technology and production processes, with juice filling lines playing a pivotal role in ensuring efficient and high-quality packaging. Juice filling line has evolved to meet the growing demands of consumers and manufacturers alike. These systems consist of a series of interconnected machines, each dedicated to specific tasks, such as bottle cleaning, filling, capping, labeling, and packaging. Automation ensures consistent product quality, minimizes human error, and optimizes production efficiency.

Automatic Juice Filling Line Features:

Quality control and safety: mango juice filling machine have stringent quality control measures in place to ensure consumer safety and satisfaction. Automated systems often include sensors and cameras that inspect each bottle for defects, such as improper sealing, leaks, or contamination. Furthermore, these lines can integrate sophisticated tracking systems to monitor production parameters, ensuring compliance with regulatory standards and reducing the risk of product recalls.

Flexibility and customization: The demand for diverse juice products has driven the need for flexible filling lines. This line can easily adapt to different bottle sizes, shapes, and materials, allowing manufacturers to cater to various consumer preferences. Quick changeover features enable seamless transitions between different juice flavors and packaging formats, reducing downtime and enhancing overall productivity.

Enhanced efficiency and cost reduction: Modern mango juice filling lines offer substantial benefits in terms of efficiency and cost reduction. The automation of tasks, reduced downtime during changeovers, and optimized production processes lead to higher output and lower operational costs. Moreover, the integration of advanced technologies enhances energy efficiency, reduces material wastage, and lowers the overall carbon footprint of the production line.

Installation and Debugging of Mango Juice Filling Machine:

- Placement: Choose a flat and dry place indoors, and place the host and conveying table smoothly after unpacking. The main machine is on the inner side of the conveying table, so that the filling head is vertically above the center of the conveying table.

- Install the conveyor: Install the conveyor belt feet and uprights stably, and the foot bolts can be slightly adjusted. Check the tightness of the conveyor chain plate, turn on the power supply, the conveyor belt should rotate smoothly, and the speed regulation should be effective.

- Configure Power: The air source used by this equipment is 0.5-0.7Mpa. The air source configured by the user should be stable to ensure the uniformity of the cylinder action to achieve accurate filling effect.

- Install light eyes: Fix the light eye according to the installation position on the conveying table, and the shooting position of each group should be accurate to achieve accurate counting effect.

- Power on: After the installation is completed according to the above operation, you can test the machine according to the operation manual of the machine.

Reviews

There are no reviews yet.