How does a bottling line work? Its main work flow includes sorting, filling, capping, foil sealing, etc.

- Automatic bottle sorting

It is mainly used to arrange the bottles in an orderly manner in the area to be filled, saving labor and improving efficiency.

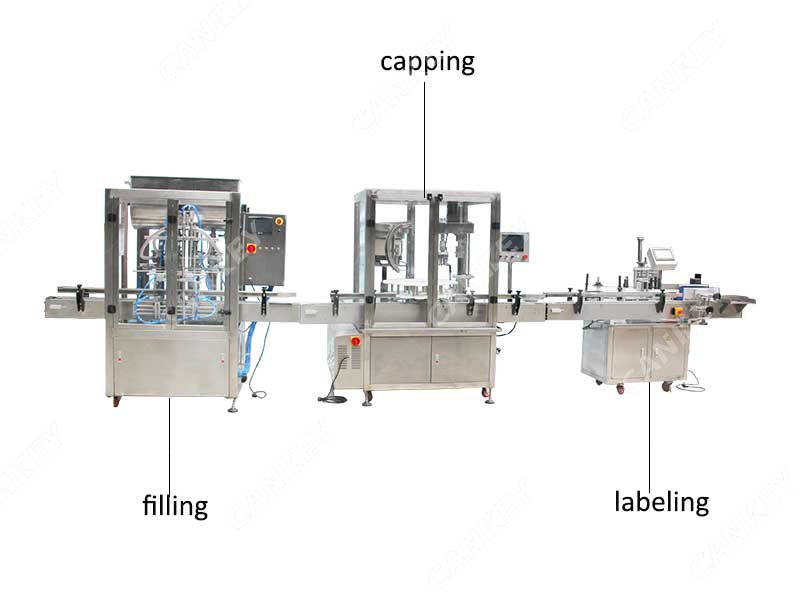

- Automatic filling

With photoelectric induction system, no bottle or lack of bottle will not be filled. Siemens electronic control PLC, easy to operate. All self-regulating air tanks incorporate individually regulated individual cylinders.

- Automatic capping

This capping machine can be used for single production or production line. Designed to handle most types of bottles, a variety of caps of different sizes can be tightened with one machine.

- Aluminum foil seal

Using the principle of electromagnetic induction, the aluminum foil on the bottle mouth instantly generates high heat, and then fuses it on the bottle mouth to achieve the purpose of sealing. It has good moisture-proof and anti-counterfeiting effects, and can prolong the storage period of items.

- Sleeve labeling machine

Integrated functions for conveying bottles, sorting bottles, automatic sleeve labels and label shrinking.

- Labeling

The bottle automatically enters the equipment, and the belt presses the bottle to walk and turn. When the bottle passes through the gluing station, the glue will automatically stick to the bottle. The label is then automatically applied to the bottle during its rotation. Can be used alone or in production line.

The above processes can be increased or decreased according to actual needs.