In today’s fast-paced industrial landscape, automation plays a pivotal role in enhancing efficiency and productivity across various sectors. One such application is the bottle filling machine, a marvel of engineering that streamlines the process of packaging liquids, powders, and particles into containers of all shapes and sizes. These machines are the backbone of industries like pharmaceuticals, food and beverages, cosmetics, and more. But do you know what is the working principle of bottle filling machine?

The basics: Bottle filling machine overview

Bottle filling machines are designed to perform a complex sequence of tasks in a highly controlled and efficient manner. These machines automate the process of dispensing and packaging materials into bottles, jars, or other containers. The working principle of these machines revolves around precision, speed, and versatility.

The primary components of a bottle filling machine include:

- Hopper or supply system: This is where the material to be filled is stored. It can be a liquid, powder, or small particles, depending on the application.

- Conveyor system: Bottles move along a conveyor belt or other automated system, positioning them underneath the filling station.

- Filling station: This is where the actual filling process takes place. The type of filling mechanism used depends on the material being filled.

- Control system: Modern bottle filling machines are equipped with advanced control systems that regulate the flow of materials, the speed of the conveyor, and other critical parameters.

- Capping or sealing mechanism: After filling, the bottles may undergo capping or sealing processes, depending on the product requirements.

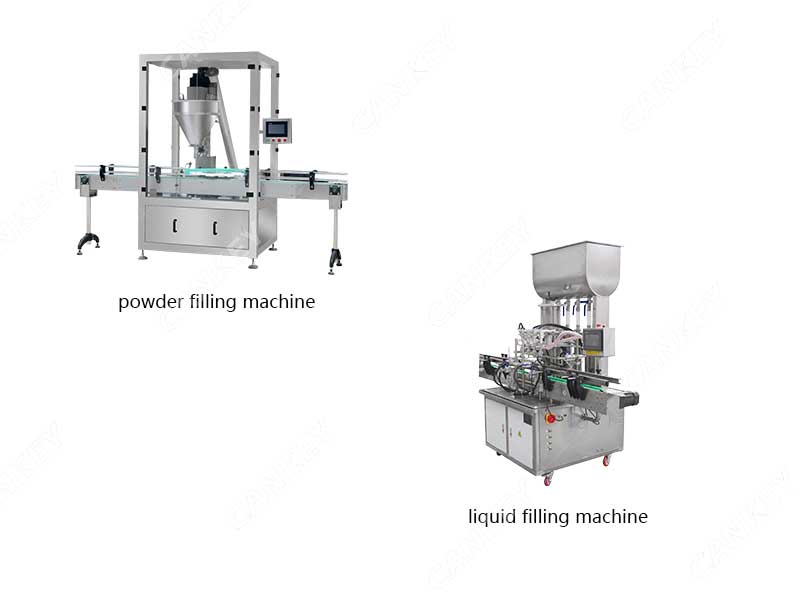

Different material, different filling mechanisms

The working principle of a bottle filling machine varies based on the material being filled. Let’s explore the principles behind filling liquid, powder, and particle materials:

1. Liquid filling:

Liquid filling involves accurately measuring and dispensing liquids into containers. Different types of liquid filling mechanisms include:

- Gravity filling: This is suitable for free-flowing liquids. The liquid flows from a storage tank into the bottles due to gravity, with the filling volume controlled by adjusting the duration of flow.

- Pressure filling: Ideal for carbonated beverages or foamy liquids, pressure filling uses a combination of pressure and time to fill the bottles accurately. The pressure prevents excess foaming.

- Volumetric filling: This mechanism uses pumps or other displacement devices to measure a specific volume of liquid before dispensing it into the bottles.

2. Powder filling:

Powder filling requires precision to prevent overfilling or spillage. Common powder filling mechanisms include:

- Auger filling: An auger (screw conveyor) moves the powdered material from a hopper into the containers. The rotation of the auger determines the amount of powder dispensed.

- Net weight filling: This method first weighs the container and then fills it with the appropriate weight of powder. It ensures accuracy even if the density of the powder varies.

3. Particle filling:

- Particle materials, like small granules or solid pieces, need specialized mechanisms to ensure uniformity. Mechanisms for particle filling include:

- Vibratory filling: Vibratory feeders dispense particles into the containers using controlled vibrations that prevent clumping and ensure a consistent flow.

- Counting filling: Used for small solid items like pills or components, this method counts a specific number of particles into each container.

Precision and consistency: The ultimate goals

The overarching goal of bottle filling machines, regardless of the material being handled, is to achieve precision and consistency in each filled container. This not only minimizes wastage but also ensures that consumers receive products of the high quality.

In conclusion, the working principle of bottle filling machines is a testament to engineering innovation and automation. These machines have revolutionized manufacturing processes by streamlining the packaging of liquids, powders, and particles. By understanding the principles behind these machines and their various mechanisms, we can truly appreciate their role in shaping modern industries and delivering products to consumers with accuracy and efficiency.