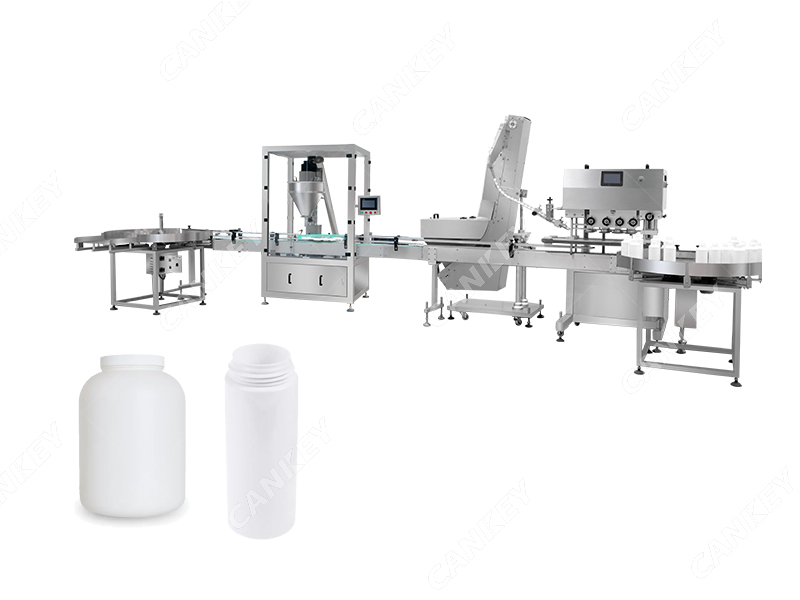

In the world of manufacturing and packaging, efficiency and precision play crucial roles in meeting consumer demands and ensuring product quality. One critical aspect of the packaging process is filling, especially when dealing with powdered substances. Powder filling machines are specialized devices designed to accurately and efficiently dispense powders into various containers. In this article, we will delve into the different types of powder filling machines, each tailored to suit specific industry needs.

Auger filling machines:

Auger filling machines are widely used in industries that deal with fine powders, such as pharmaceuticals, food, and chemical manufacturing. The machine comprises a screw (auger) inside a hopper, which rotates to transport the powder from the hopper into the containers. The rotation speed of the auger determines the amount of powder dispensed, ensuring precise measurements for each filling.

Volumetric cup filling machines:

The machines employ a simple yet effective method for filling powders. The machine utilizes pre-calibrated cups that measure a specific volume of powder and then dispense it into containers. This type of machine is suitable for free-flowing powders, like granules or small particles, and is often found in the food industry for packaging products like sugar, salt, and spices.

Vertical form fill seal (VFFS) machines

VFFS machines are advanced, fully automated packaging systems that create a bag from a roll of film, fill it with powder, and then seal it. The machines can handle a variety of powders, from fine to coarse, and are commonly used for packaging products like coffee, flour, and protein powders. VFFS machines offer high-speed filling capabilities and are favored for their efficiency in large-scale production environments.

Horizontal form fill seal (HFFS) machines

Similar to VFFS machines, HFFS machines are automated systems that create bags from a roll of film. However, they differ in the orientation of the bag formation, with HFFS machines producing horizontally oriented bags. These machines are preferred for filling powders with specific properties, such as instant soup mixes, sugar sachets, and dry beverage mixes.

Powder filling machines are indispensable assets in various industries, ensuring accurate, efficient, and hygienic packaging of powdered products. Depending on the type of powder and specific packaging requirements, manufacturers can choose from a variety of filling machines.

As technology advances, we can expect further refinements and innovations in powder filling machinery, enhancing productivity and product quality in the packaging industry.